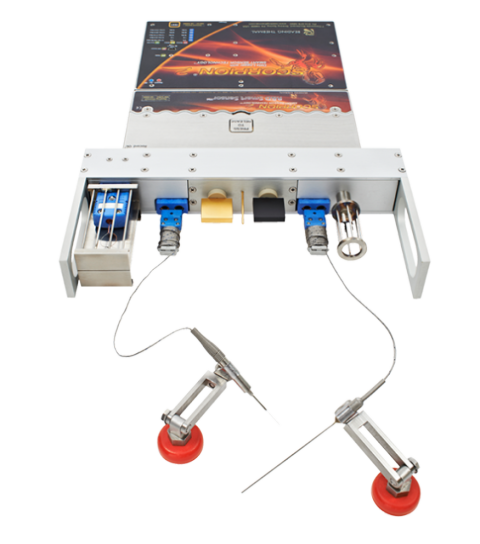

The R&D Smart Sensor™ is a multi-element sensor enabling the collection of 4 key baking parameters in a single pass through a process. The user quickly gathers a complete set of profiles characterizing Environment Temp, Product Core Temp, Airflow and Energy Transfer. To collect this data using individual sensors would typically require four passes through an oven. With its very small footprint, only 254mm (10”) wide and only 40mm (2”) of headroom required, the R&D Smart Sensor™ will pass through virtually any process.

The SCORPION® 2 R&D Smart Sensor is best used by the R&D/Corporate Engineer who needs the ability to quickly profile an oven. This person is interested in benchmarking an oven for R&D purposes, product development, product transfer and oven matching across the company’s baking platforms. This person is not interested in studying side-to-side temperature or airflow variation which would require individual, much larger, temperature and air velocity sensor arrays to span the conveyor width.

There are two types of Pluggable Temperature Sensors available:

Type A, used on solid or tight mesh conveyors, is an Air/Band sensor designed to measure air temperature immediately above the conveyor, and surface temperature of the conveyor itself. Type A can only be used with the THB40 & THB50 Thermal Barriers.

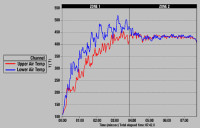

Type B, used on open mesh conveyors, is an Air/Air sensor designed to measure upper air temperature immediately above the conveyor, and lower air temperature of the air rising through the conveyor. The upper and lower thermocouples are separated by a thin shield.

Analyzing the Results

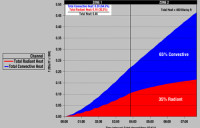

The SCORPION® Software (SV8) stores the data gathered by the sensors and can be displayed in a variety of ways, giving you a visual representation of what is happening inside your oven.