The characteristics of baked goods are defined by the type and amount heat applied to them during the baking process, and all commercial baking ovens bake differently. Optimize the conditions in your oven by monitoring temperature, heat flux, air velocity, and humidity with the innovative SCORPION® 2 Profiling System and Data Logger manufactured by Reading Thermal.

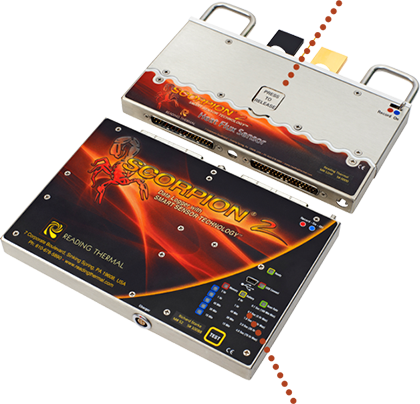

The experts at Reading Thermal, a Reading Bakery Systems brand, have researched and investigated the commercial baking process for more than 25 years. The team developed and supports the SCORPION® 2 Profiling System and Data Logger, now an industry standard, that measures and maps essential baking parameters that affect the quality of your baked goods.

Importance of Temperature Profiling

Product level temperature throughout an oven can make the difference between optimum quality and throughput – and wasteful, under-baked, or burnt product. The process of fermentation, product swelling, moisture evaporation, flavor development, and surface coloring are all time and temperature dependent. For example:

- Insufficient heat during baking can cause crusts to be brittle or dry,

- Insufficient heat during baking can create products that are too light in color.

- Insufficient heat during baking can create a structure that is too dense.

- Excessive heat can cause the bottoms of loaves to burn before the crusts brown correctly.

- Excessive heat will cause moisture to evaporate too quickly, and the dough to rise unevenly.

How to Measure Oven Temperature

Reading Thermal designed the SCORPION® 2 Temperature Sensor Array to measure temperature at product level, in fixed positions across the conveyor, and deliver a true representation of what your product is experiencing over time. Different types of pluggable sensors are available, including one designed for solid or tight mesh conveyors and one for open mesh conveyors.

The sensor array is connected to the SCORPION® 2 Data Logging Measurement System and travels through the oven with the product, yielding a precise picture of temperature from side-to-side and end-to-end.

After gathering the data, the SCORPION® Software (SV8) Food Safety Module simplifies the calculation of lethality and generates a comprehensive report that displays cumulative log reduction. By combining this ease of measurement with robust data capture, the SCORPION® 2 Profiling System makes it simple to optimize your process and products while meeting food safety standards.

Other Smart Sensors and Sensor Arrays

Airflow affects the coloration, texture, firmness, and baking time of your final product. Measure oven air velocity with the SCORPION® 2 Air Velocity Sensor.

The SCORPION® 2 Heat Flux Sensor measures convective and radiant heat fluxes at product level and displays the results in Btu/hr·ft2 or W/m2.

Humidity affects finished product quality in many ways. Bakeries around the world rely on the SCORPION® 2 Humidity Sensor to measure the absolute moisture content of the thermal environment in both heating and cooling processes.

Improve your commercial bread, bun, and snack manufacturing process by thermal profiling with the SCORPION® 2 Profiling System from Reading Thermal. Contact us online, or call us at (610) 678-5890 Ext. 2 to learn more.