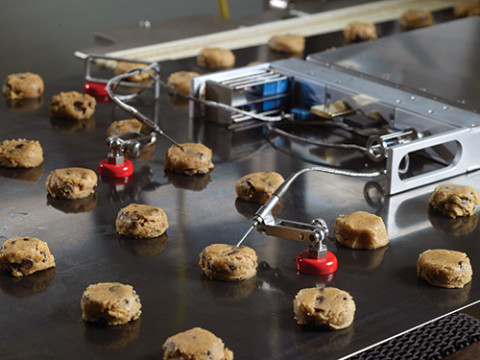

The application of thermal profile analyzers for baking consistency from Reading Thermal enables industrial and commercial bakeries to set up temperature controls for baking processes and record data at various points along the production line. Not only does this keep your team accountable for consistently evaluating products during baking, but using a system like this can also help improve efficiency while helping ensure quality control at all levels of production by accurately measuring and profiling key baking parameters used throughout the baking process.

Baking is an incredibly delicate, sensitive profession. The slightest change in temperature or ingredient can result in an entirely different final product. This is why commercial and industrial bakeries rely on precise measurements and processes to ensure their customers receive the same delicious baked goods with every purchase. That’s where Reading Thermal comes in – offering thermal profile analyzers that can monitor and maintain the perfect baking temperatures throughout the entire baking process. With these analyzers, bakeries can produce the same product time and time again, keeping their customers satisfied and coming back for more.

Building a Thermal Profile

Thermal profiles consist of several measurements taken throughout the baking process. These key baking parameters are the metrics by which your products are made, influencing their texture, flavor, interior, exterior, and shelf-life. The four parameters are:

- Temperature

- Air Flow

- Humidity

- Heat Flux

By recording these metrics and compiling them into a single thermal profile, bakers can analyze, visualize, and make adjustments based on real-time information gathered from their normal baking processes. Using these thermal profiles as a template ensures that bakers can standardize oven environments across multiple lines, allowing them to bake consistent products even when using different ovens with different settings, designs, and configurations.

What matters most is that thermal profiles allow bakeries to have a precise visual of how their ovens operate during the baking process. Hot and cold zones, steam injection amounts, humidity levels, baking time, and temperature variations can all be identified through the thermal profile, allowing bakers to make fine-tune adjustments.

Measuring Oven Environments

Our SCORPION® 2 Profiling System is ideal for compiling any and all actionable data regarding your key baking parameters across every oven line. The combination of our SCORPION® 2 Data Logger and Smart Sensor technologies enable bakeries to accurately measure and record temperatures throughout their ovens, helping them understand the physical environment of each line as well as how to adjust baking parameters to improve product quality, safety, and productivity.

Heat Flux Sensor

The SCORPION® 2 Heat Flux Sensor measures heat and how it’s applied in the baking process, measuring convective and radiant energy transfer at product level.

Temperature Sensor Array

The SCORPION® 2 Temperature Sensor Array measures total temperature levels at product level, helping bakers understand the temperature uniformity within their ovens.

Digital Air Velocity Sensor Array

The SCORPION® 2 Digital Air Velocity Sensor Array measures the distribution of air flow throughout the baking process, helping bakers understand the air velocity and patterns at each stage of production.

Digital Humidity Sensor

The SCORPION® 2 Digital Humidity Sensor measures humidity levels in your ovens, ensuring bakers can adjust moisture content according to what their products need.

The use of these and other Smart Sensors, Reading Thermal empowers bakeries to adequately use thermal profile analyzers for baking consistency, leveraging data to make their baking processes more efficient, safe, and consistent. If you’re interested in our solutions, call us at (610) 678-5890 Ext. 2, or contact us online for more details about our innovative products.