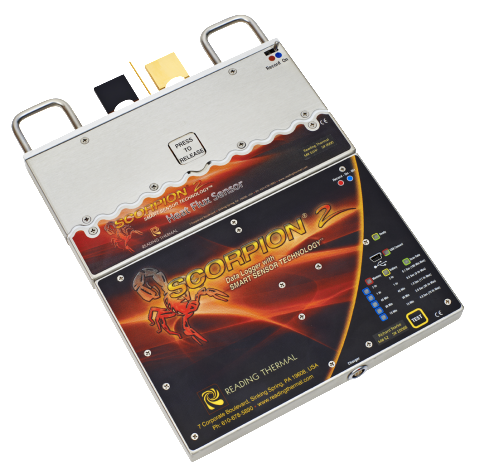

Reading Thermal offers real-time temperature sensors for commercial oven systems that offer myriad benefits, from ensuring consistent product quality to enhancing food safety compliance. By providing instant visibility into oven conditions, real-time temperature monitoring enables bakery operators to optimize baking processes, minimize product defects, and improve overall efficiency. Our experts would like to share more success stories and the benefits of real-time temperature monitoring with you.

Consistent Product Quality

Real-time temperature monitoring ensures that bakery ovens maintain precise temperature settings throughout baking. Our system works by placing sensors at strategic points within the oven, which continuously measure the temperature and send real-time data to a central control unit. This unit then adjusts the oven’s heating elements to maintain the desired temperature, resulting in consistent product quality across batches. By continuously monitoring oven temperatures and making real-time adjustments, bakery operators can prevent over-baking, under-baking, or uneven baking, ensuring that every product meets the desired taste, texture, and appearance standards.

Enhanced Food Safety

Real-time temperature monitoring also helps bakery operators comply with food safety regulations by ensuring products are baked to the required internal temperatures to kill harmful bacteria and pathogens. By monitoring oven temperatures in real-time, bakery operators can quickly identify and address deviations from the desired temperature ranges, reducing the risk of foodborne illness and ensuring consumer safety.

Improved Process Control

In addition, our sensors provide bakery operators with instant feedback on oven performance, enabling them to maintain optimal baking conditions and respond quickly to changes in production requirements. They promote consistent product quality and minimize downtime, increasing productivity and profitability.

Energy Efficiency

Reading Thermal sensors also help bakery operators optimize energy usage by ensuring that ovens operate at peak efficiency. They help operators reduce energy consumption and lower operating costs without compromising product quality or production output, leading to improved profitability and sustainability for bakery operations.

Remote Monitoring and Control

Advanced real-time temperature sensors from Reading Thermal are not only powerful but also user-friendly. They offer remote monitoring and control capabilities, allowing bakery operators to monitor oven conditions and adjust from anywhere with an internet connection. This flexibility enables bakery operators to manage multiple ovens simultaneously, monitor production progress remotely, and respond quickly to any issues or alarms, all with a simple and intuitive interface. This improves operational efficiency and reduces the need for on-site supervision, making your job easier.

Data Logging and Analysis

Real-time temperature monitoring sensors also include data logging and analysis features that allow bakery operators to track temperature data over time, analyze trends, and identify opportunities for process optimization. By analyzing temperature data collected from bakery ovens, operators can gain insights into oven performance, identify areas for improvement, and implement targeted interventions to enhance productivity and product quality.

Compliance Reporting

In addition, our real-time temperature monitoring sensors help bakery operators generate compliance reports for food safety audits and regulatory inspections. These systems streamline the compliance reporting process, saving time and reducing the risk of errors or discrepancies. This ensures that bakery operations comply with food safety regulations and industry standards, maintaining consumer trust and confidence in the quality and safety of baked goods. By investing in our system, you’re not just improving your operations, you’re also enhancing your bakery’s reputation as a provider of safe and high-quality products.

By investing in real-time temperature monitoring sensors for commercial oven systems from Reading Thermal, you are not just investing in a product but in the reliability and performance that our brand represents. Our sensors can help you optimize baking processes, minimize product defects, and improve overall efficiency, leading to increased productivity, profitability, and competitiveness in the market. The experts with Reading Thermal, always ready to support you, would love the opportunity to tell you more. Just give us a call at 610-678-5890 or use our online contact form to get in touch.

We look forward to hearing from you.