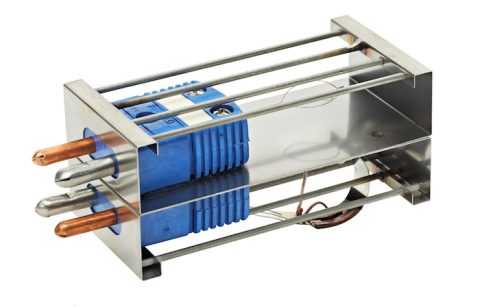

Baking is as much a science as it is an art. While creativity plays a role in developing delicious recipes, precision is what ensures those recipes turn out right every time. Even small temperature variations can make a huge difference in the final product, affecting everything from texture to moisture content. Reading Thermal’s SCORPION® 2 Data Logger – the clear leader among temperature data logging solutions for commercial bakeries provides real-time insights. These insights help bakers fine-tune their methods, reduce waste, and produce consistently high-quality baked goods.

The Role of Temperature in Baking Precision

Temperature affects every stage of baking, from dough fermentation to the final crust color. If an oven runs hotter or cooler than expected, it can throw off the entire process. Bread may not rise properly, cookies may spread too much, and cakes may come out dry or dense. Without accurate temperature monitoring, it’s impossible to know if the oven is truly operating at the right levels.

The SCORPION® 2 Data Logger continuously records temperature fluctuations, creating a detailed profile of how heat moves through the oven. This information helps bakers understand where inconsistencies occur and allows them to make the necessary adjustments. With this level of control, bakeries can maintain the exact conditions needed to achieve perfect results with every batch.

Improving Consistency with Data Logging

One of the biggest challenges in commercial baking is maintaining consistency across multiple production runs. Customers expect the same taste, texture and appearance every time they buy a product. But without precise temperature control, even the best recipes can produce unpredictable results.

Data logging eliminates the guesswork by providing measurable, repeatable temperature data. Instead of relying on manual oven readings or assumptions, bakeries can track temperature changes in real-time. If certain areas of the oven run hotter or cooler, adjustments can be made to balance heat distribution. This ensures that products bake evenly and consistently, no matter how large the batch.

Temperature logging also helps with standardizing recipes. If a bakery expands production to new locations, the same temperature data can be used to replicate baking conditions across different ovens. This guarantees that customers get the same quality product, whether they’re visiting a bakery across town or across the country.

Reducing Waste and Improving Efficiency

When oven temperatures fluctuate, batches can become overbaked, underbaked, or unevenly cooked. This leads to wasted ingredients, lost time, and higher production costs. A single faulty batch can mean throwing away dozens – or even hundreds – of products.

The SCORPION® 2 Data Logger makes it easy for bakeries to identify issues before they become costly mistakes. If an oven is heating unevenly, adjustments can be made before an entire batch is ruined. By catching temperature inconsistencies early, bakeries can reduce waste, improve efficiency and ensure more products make it to customers in perfect condition.

Optimizing oven performance with data logging also helps reduce energy consumption. Ovens that run too hot or cycle on and off frequently use more energy than necessary. With detailed temperature tracking, bakeries can adjust settings to improve efficiency, lowering energy costs without sacrificing product quality.

The Long-Term Benefits of Temperature Data Logging

Bakeries that invest in temperature data logging gain long-term advantages. By maintaining precise baking conditions, they produce consistently high-quality products, improve operational efficiency, and reduce costly waste. Over time, this leads to greater profitability and a stronger reputation for quality.

For more information on the SCORPION® 2 Data Logger from Reading Thermal, call 610-678-5890 or use our online form.