In the world of large-scale industrial baking, maintaining precise control over oven conditions is paramount. Even slight deviations in temperature and humidity can significantly impact product quality, consistency, and safety. This is where temperature and humidity data loggers for large industrial ovens from Reading Thermal become indispensable tools.

Ensuring Consistent Product Quality

Imagine biting into your favorite baked good, expecting that perfect texture and flavor, only to be met with disappointment. Inconsistent oven conditions can lead to such letdowns. Temperature and humidity data loggers monitor these critical parameters in real-time, ensuring that each batch meets the desired specifications. By capturing detailed profiles of the baking environment, these devices help bakers identify and rectify inconsistencies, leading to uniform and high-quality products.

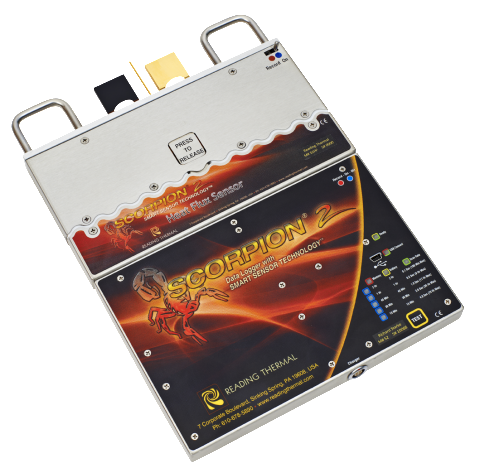

Industrial ovens operate on precise temperature controls, but external factors such as airflow disruptions, ingredient variations and seasonal humidity changes can alter the baking environment. Without accurate data, inconsistencies in texture, moisture retention and overall product quality can arise. Our SCORPION® 2 Data Logger helps bakeries analyze historical trends and fine-tune their processes to prevent deviations from ideal baking conditions.

Enhancing Process Efficiency

Efficiency is the backbone of any successful industrial operation. Data loggers provide insights into the thermal processes within ovens, allowing for optimization of baking times and energy consumption. By analyzing the collected data, bakeries can achieve optimal results with minimal resource expenditure. This not only boosts productivity but also contributes to significant cost savings over time.

Many bakeries struggle with energy efficiency due to unnecessary heat loss or excessive baking times. Businesses can use the SCORPION® 2 Data Logger to identify inefficiencies in their ovens and make precise adjustments that reduce energy waste. This ensures that the oven reaches and maintains the desired temperature with minimal fluctuation, which not only preserves resources but also accelerates the baking process without compromising quality.

Ensuring Food Safety and Compliance

Food safety is non-negotiable in the baking industry. Maintaining appropriate temperature levels is crucial to ensure that products are baked thoroughly, eliminating potential pathogens. Data loggers play a vital role in verifying that ovens consistently reach and maintain the necessary temperatures, providing documented evidence for compliance with food safety regulations. This documentation is invaluable during audits and helps in adhering to standards set by food safety authorities.

Regulatory agencies have strict guidelines for food safety, particularly when it comes to temperature monitoring and documentation. Failure to comply with these standards can lead to product recalls, legal issues, and reputational damage. By integrating temperature and humidity data loggers into their processes, bakeries can provide proof of compliance and ensure that each batch meets safety requirements before it reaches consumers.

Reading Thermal’s SCORPION® 2 Digital Humidity Sensor provides critical data on moisture levels inside ovens. Excess humidity can lead to underbaked centers, while too little humidity can cause products to dry out too quickly. Carefully balancing moisture levels helps bakeries extend shelf life and improve product texture, further enhancing food safety measures.

Get in Touch to Learn More

By using temperature and humidity data loggers for large industrial ovens from Reading Thermal, bakeries can not only maintain the highest quality standards but also improve efficiency, reduce waste and ensure compliance with food safety regulations. Investing in the right technology ensures that every batch is produced under optimal conditions, giving bakeries a competitive edge in today’s demanding market. Learn more by contacting us online or calling 610-678-5890.