To bake your products to perfection, you must know what is happening inside your industrial oven. Optimizing baking processes with thermal profiling systems from Reading Thermal, will provide information you can use to make reliable data-based decisions about your processes and products.

Reading Thermal, headquartered in Sinking Spring, Pennsylvania, has been focused on measuring and understanding the commercial baking process for more than 25 years.

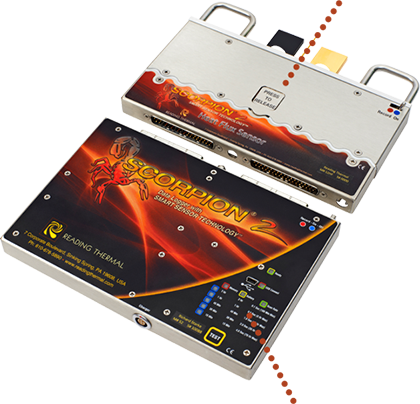

The SCORPION® 2 Profiling System enables you to monitor actual in-process conditions and get the critical information you need to correct problems and maintain optimum process control. This powerful diagnostic tool has become an industry standard for understanding and improving your proofing, baking, cooling and freezing processes.

Measuring Temperature

If you manufacture bread, biscuits, rolls, hamburger buns, cakes, or other bread products, you know that several stages of the process are temperature-dependent, such as oven-spring, drying/dehydration, and color formation. Too much heat coming from one direction in the oven can cause the bottoms of the loaves to burn before the crusts brown properly.

The Reading Thermal SCORPION® 2 Temperature Sensor Array measures temperature at product level, in fixed positions across the conveyor, and delivers a true representation of what your product is experiencing over time. Different types of pluggable sensors are available, including one designed for solid or tight mesh conveyors and one for open mesh conveyors. Our state-of-the-art profiling system also provides an easy way to validate your kill step for food safety and FSMA compliance.

Measuring Air Velocity

Air velocity is the measurement of airflow inside the oven. This measurement is important because, along with other parameters, air velocity influences the coloration, texture, firmness, and baking time of your final product.

Air flow can be measured and recorded with the SCORPION® 2 Air Velocity Sensor. The sensor array delivers a precise picture of airflow patterns inside the oven. The sensors collect data, at product level, as the array travels through the oven. The number of sensors varies with the width of the conveyor.

Measuring Humidity

The moisture inside your oven often comes from the product itself and represents a delicate balance that can impact the quality of finished products. For example, humid air transfers heat to products more efficiently, cooking them more rapidly. Low humidity typically results in crustier bread, while high humidity can lighten the color of the crust and prevent it from burning.

The new SCORPION® 2 Digital Humidity Sensor is designed to measure the moisture content, of the thermal environment, in both heating and cooling processes. It is applicable to proofers, ovens, dryers and cooling tunnels.

Measuring Heat Flux

Oven heat flux refers to the amount of energy transferred per unit area per unit time from or to a surface. It is the best non-intrusive indicator of the performance of ovens during baking in terms of the product.

The SCORPION® 2 Heat Flux Sensor measures convective and radiant heat fluxes at product level, and display the results in Btu/hr·ft2 or W/m2. The sensor travels through the process with the product, and the oven under full load, producing a precise profile of heat flux components experienced by the product.

If you are experiencing inconsistent product quality, optimizing your baking processes with thermal profiling may be the answer. You can count on the state-of-the-art Reading Thermal SCORPION® 2 Data Logger and our various sensors and sensor arrays. Contact us online, or call our headquarters in Sinking Spring, Pennsylvania at (610) 678-5890 Ext. 2 to learn more about our innovative products.