Baking is an exact science, and as a commercial bakery, you know the way the air moves in your ovens can have a major impact on the outcome of your baked goods. Having too much heat or not enough – due to improper air flow throughout your space – may leave you with results that are less than satisfactory or can even cause spoilage of the product. To get it just right, industrial oven air velocity monitoring can be implemented to better understand and control this environment. By investing in quality equipment such as sensors to measure the distance particles are moving within each area of the baking space at regular intervals, producers can gain real-time readings for accurate temperature across their operations.

Reading Thermal is a leader in the industry when it comes to providing the best solutions for industrial oven air velocity monitoring. Our Smart Sensors provide up-to-date data and information on the exact conditions of your baking environment, with intuitive readings that make it easy for anyone working on your line to understand. With our reliable monitoring systems, your bakery will be able to guarantee top-notch quality and safe performance at all times.

How to Use Air Velocity for Oven Optimization

If you’re looking for the best results when using an oven, you need to make sure that the air velocity is optimal. This means measuring, adjusting and optimizing your oven for maximum efficiency.

Air velocity refers to how fast air moves through a certain area. It’s important in the baking process because it determines how evenly heat is distributed in the oven.

When an oven is too hot, it can lead to uneven baking or even burning of your food. On the other hand, if the oven air velocity is low, it can cause food to cook too slowly.

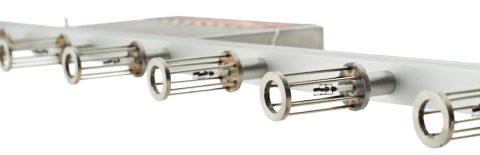

In order to measure and adjust your oven air velocity correctly, you need to use a tool that will accurately measure airflow. In this instance, that tool is our SCORPION® 2 Digital Air Velocity Sensor Array, providing a side-to-side and end-to-end profile of your oven’s complete air velocity baking parameters.

The Digital Air Velocity Sensor Array uses thin-film platinum RTD hot-wire anemometers, strategically placed along a fixed position and attached to our SCORPION® 2 Data Logger, which is then run through an entire baking cycle.

Once the data is collected, you can use our proprietary SCORPION® Software Version 8 (SV8) to view a detailed report of your oven’s air velocity. This information will help you identify any weak points in your baking process that need improvement. These report come in two different visual formats:

- A 2D line graph

- A 3D mesh graph

2D Line Graph

The 2D Line Graph shows the air velocity at each location over time, providing a clear picture of side-to-side variation across the conveyor line. Tighter lines mean more even airflow distribution across the width of the band.

3D Mesh Graph

The 3D Mesh Graph is a visual representation of the same data as the 2D line graph. It shows an animated surface plot of the air velocity at each location over time. This graph is useful for visualizing any areas where there may be weak airflow distribution.

By using our SCORPION® 2 Digital Air Velocity Sensor Array for industrial oven air velocity monitoring for baking, you can ensure optimal baking results every time. If you’re interested in our services, call us at (610) 678-5890 Ext. 2, or contact us online for more details about our innovative products.