In large-scale industrial baking, precision is everything. Even minor fluctuations in humidity can lead to inconsistencies in texture, moisture retention, and overall product quality. When products don’t meet the right standards, they often end up as waste, costing bakeries valuable time, money, and resources. Using humidity data loggers to improve baking processes in bakery production lines is critical. Reading Thermal products help bakeries reduce waste and improve efficiency.

Identifying and Preventing Waste in Large-Scale Baking

Humidity data loggers do more than just track moisture levels; they provide an advanced level of precision that manual monitoring simply can’t achieve. In a busy industrial bakery, where thousands of products are made daily, small inconsistencies can result in significant waste. By continuously measuring humidity levels, bakeries can identify problem areas before they lead to large-scale product losses.

One of the key advantages of using a humidity data logger is the ability to detect trends over time. By analyzing historical data, bakeries can recognize seasonal humidity changes, ingredient variations, and other factors that might impact production. Instead of reacting to quality issues after they arise, bakeries can make proactive adjustments to maintain consistency. This level of predictive control minimizes product rejections and helps ensure that every batch meets strict quality standards.

Real-Time Adjustments for Immediate Waste Reduction

With real-time humidity data at their fingertips, bakers can make quick adjustments during the baking process. If a humidity fluctuation is detected mid-bake, settings can be modified immediately to prevent an entire batch from being ruined. This capability is crucial for reducing waste, as it allows bakeries to resolve problems before they escalate.

Balancing Temperature and Humidity for Optimal Baking

Temperature and humidity must work together to achieve the best baking results. If humidity is too high, bread and pastries may not develop the proper crust or texture. If it is too low, products may dry out too quickly, affecting shelf life and consumer satisfaction. Specialty baked goods, such as artisan bread, require precise humidity levels during proofing and baking to achieve their signature textures.

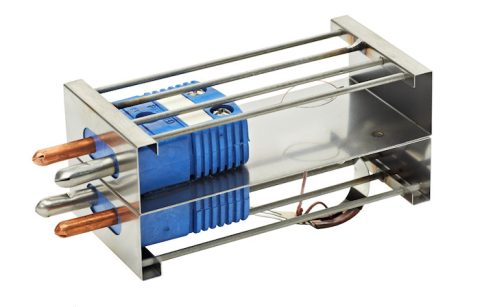

Reading Thermal’s SCORPION® 2 Digital Humidity Sensor, makes it easy for bakeries to accurately measure and control both temperature and humidity in their ovens. This advanced tool provides precise moisture readings within the baking chamber, ensuring that the ideal conditions are maintained for every product type. By integrating a high-quality data logger into their processes, bakeries can reduce inconsistencies, improve texture, and maximize product freshness.

The Importance of Humidity Control in Cooling

Humidity doesn’t just affect baking – it also plays a critical role in the cooling stage. When bakery products leave the oven, they must cool properly to prevent condensation inside packaging. Excess moisture trapped in packaging can lead to mold growth and premature spoilage, contributing to unnecessary food waste.

By using humidity data loggers during cooling, bakeries can ensure that products retain their freshness for longer periods. Reading Thermal’s SCORPION® 2 System provides real-time insights into humidity conditions during cooling, allowing bakeries to fine-tune their processes and reduce spoilage-related waste. With better control over moisture content, bakeries can extend product shelf life, ensuring that fewer items go to waste at the consumer level.

If you would like more information on using our humidity data loggers to improve baking processes in bakery production lines, please use our online form or call Reading Thermal at 610-678-5890.