Baking is both an art and a science, requiring a deft touch to create perfection. The key ingredients of great results are time, temperature, materials, and the skill of the baker—but what about air? Air velocity profiling can be just as important in delivering top-notch recipes. By understanding how air moves through ovens at different temperatures, bakers can ensure that heat evenly reaches every part of their baking pans or trays for consistently delicious results. To ensure an accurate profile is developed, bakers need resilient, precise sensors specifically designed for high temperature air velocity profiling for baking perfect, consistent products.

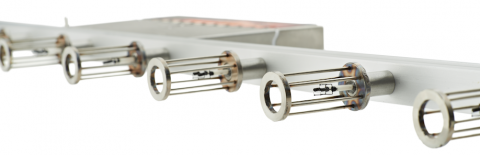

When it comes to measuring and controlling air velocity at high temperatures, Reading Thermal is one of the industry-defining manufacturers of technology. Our SCORPION® 2 Digital Air Velocity Sensor Array provides bakers with real-time feedback on oven performance and accuracy. Our technology is designed to retain accurate measurements at extremely high temperatures, capable of creating accurate profiles up to 662 degrees Fahrenheit. It’s a comprehensive tool that allows bakers to gain a true understanding of how air velocity affects their products across multiple oven lines, paving the way for immediate adjustments to oven condition parameters to achieve desired consistency.

What Is Air Velocity in an Oven Setting?

Air velocity is the speed at which air moves within an oven chamber or over a product. Bakers can use this data to gauge the accuracy of their baking process, as it gives them insight into how heat and hot air are distributed within the oven.

This information is invaluable when trying to achieve consistent results across multiple trays, pans or lines. By understanding how air flows around an oven cavity, bakers can determine if certain areas are generating more heat than others, adjust airflow accordingly, and create perfectly cooked products every time.

This is the broadest possible explanation of air velocity and how it impacts your baking processes, but it only covers part of the inherent complexity in managing and controlling your oven airflow conditions. For instance, depending on the type of oven you’re using – i.e. radiant vs. convection ovens – airflow is distributed by different means.

The distribution method influences how each oven’s air velocity should be adjusted, ultimately determining how much heat should be delivered to a product. This is why having the right tools for measuring air velocity, such as Reading Thermal’s SCORPION® 2 Digital Air Velocity Sensor Array, is so important for bakers looking to achieve consistent results.

2D Line Graph

One of the graphs used to measure and analyze data gathered by our SCORPION® 2 Digital Air Velocity Sensor Array is a 2D Line Graph. This channel uses multiple colored lines, measuring spikes in temperature along a side-to-side compilation of your conveyor belt to determine consistency in air velocity temperature. Essentially, the tighter the patterns, the more even the airflow is. If lines are unfocused and spread out, air velocity is not uniform across the conveyor belt.

3D Mesh Graph

By visualizing air velocity temperatures in a 3D mesh graph, bakers can easily see how air velocity is impacting their baking results. With this graph, bakers can view temperature distribution across the conveyor belt in terms of higher airflow vs. lower airflow, highlighting different baking zones and how concentrated air velocity is.

No matter how hot your ovens get, Reading Thermal has a solution for providing high temperature air velocity profiling for baking. If you’re interested in our services, call us at (610) 678-5890 Ext. 2, or contact us online for more details about our innovative products.