High rate baking means products will be done sooner, but some troubleshooting may be necessary. Reading Thermal can help you bake your products to perfection and learn what is happening inside your bakery oven.

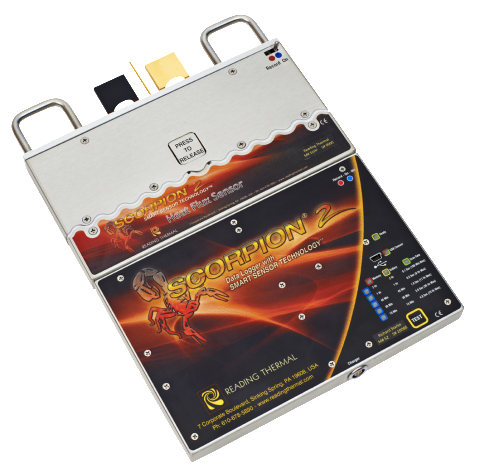

Consider the SCORPION® 2 Data Logger to measure parameters of your industrial ovens that have an impact on the quality of your products.

Why Measure Oven Temperature?

If you manufacture bread, artisan bread, rolls, biscuits, hamburger buns, cakes, or similar products, you know oven temperature is responsible for chemical and physical reactions in your dough or batter, and temperature extremes during baking (whether too high or too low) leads to fermentation and humidity level changes.

An oven that is too cool can produce products with color that is too light. The product structure could also be too compact because few air bubbles were developed in the baking process. This can result in a heavy, unappealing loaf with a soft, pale crust.

An oven with too much heat coming from one direction can cause the loaf bottoms to burn before the crusts are browned properly. Typically the surface color will be too dark and the product may not rise evenly, resulting in several surface cracks.

How to Measure Oven Temperature

The Reading Thermal SCORPION® 2 Temperature Sensor Array travels through the oven with your product(s), measuring temperature at product level in fixed positions across the conveyor. It delivers a precise picture of temperature from side-to-side and end-to-end and a true representation of what your product is experiencing over time.

Different pluggable sensors are available, including one designed for solid or tight mesh conveyors and one for open mesh conveyors.

Profiling Bread & Bun Ovens

Unlike cracker and biscuit tunnel ovens where the SCORPION® 2 can ride on the conveyor, a bread and bun oven requires a specialized carrier. To produce accurate and repeatable data collection, placement is critical. Long bake times and the Bake Cycle S-Curve caused Reading Thermal to design solutions just for the bread and bun baker.

Temp+Airflow Sensor Array: This tool simultaneously profiles temperature and airflow across the width of large tray and grid conveyor ovens. It features nine Temp+Airflow sensors spaced evenly across an aluminum bar. It is available in three sizes to match the widths of the most popular bread oven conveyors.

Pan+Dough Probe: This tool is comprise of a copper plate that is placed in the pan and remains in a fixed position as it travels through the oven. It simultaneously captures the pan/dough interface temperature and the dough core temperature. This probe provides accurate repeatable results that are not achievable with hand-placed thermocouples. It connects to the Temperature Interface device which can accommodate five dual probes.

Bake Cycle S-Curve Analysis: The Bake Cycle S-Curve Analysis optimizes the baking profile and provides the critical insight needed to make adjustments to ingredients, bake time, and zone temperature settings. SCORPION® Software Version 8 (SV8) automatically calculates the three key S-Curve data points: Yeast Kill, Gelatinization and Arrival.

If you are experiencing inconsistent product quality, troubleshooting your high-rate baking process may be the perfect solution. Count on the state-of-the-art Reading Thermal SCORPION® 2 Data Logger and our various sensors and sensor arrays. Call our headquarters in Sinking Spring, Pennsylvania at (610) 678-5890 Ext. 2, or contact us online to review your options.