Need reliable kill step validation of your baking process for FSMA compliance? Look no further than the innovative Reading Thermal SCORPION® 2 Data Logger and our various sensors and sensor arrays.

Reading Thermal manufactures and supports the SCORPION® 2 Data Logger, a state-of-the-art tool that is now a standard in the baking industry and provides an easy way to validate your kill step for food safety.

About Kill Step Validation

Food-borne pathogens can be introduced into baked goods and other food by means of ingredients, unhygienic handling, pests, and environmental factors.

Rather than respond to safety failures after baking is complete, the Kill-Step Validation requirements of the FDA’s Food Safety Modernization Act (FSMA) are designed to prevent the failures and provide documented evidence.

The only way to confirm that your baking process consistently delivers the desired lethal result to ensure the destruction of pathogenic microorganisms like Salmonella spp or E. coli is with scientific proof.

The SCORPION® 2 enables you to monitor actual in-process conditions and acquire the critical information needed to maintain optimal process control and correct any problems. It is a powerful diagnostic tool for understanding and improving your proofing, baking, cooling, and freezing processes.

It’s important to recognize that temperature, air velocity, humidity, and heat flux are interconnected. They work together to control final product quality; humidity, for example, is affected by air velocity and temperature.

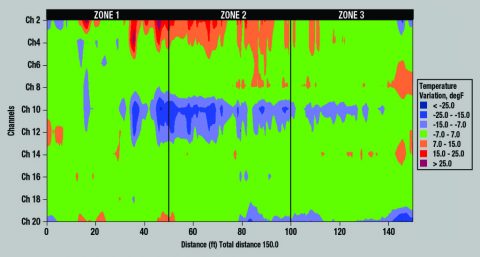

The SCORPION® 2 Temperature Sensor Array measures temperature at product level, in fixed positions across the conveyor, and delivers an accurate representation of what your product is experiencing over time. Different types of pluggable sensors are available, including sensors designed for solid or tight mesh and open mesh conveyors.

Connect our different smart sensors and sensor arrays to the SCORPION® 2 Data Logger and pass them through the oven with your product(s) to capture the four main baking parameters: temperature of the environment (including the temperature of both the air and the oven belt surface), humidity, heat flux (energy transfer), and airflow (velocity).

Kill Step Calculators

The kill step is required in order to eliminate harmful pathogens and reduce the microbial load in food to safe levels. With the SCORPION® 2 Data Logger, you can use AIB International’s Kill Step Calculators to evaluate the lethality of your process.

There are kill step calculators for specific bakery products, including hamburger buns, round top cake muffins, nut muffins, fruit-filled pastry, crispy cookies, soft cookies, multigrain bread, 100% whole wheat multigrain bread, yeast-raised donuts, flour tortillas, and cheesecake. Download the procedures and calculators here.

Consider the state-of-the-art Reading Thermal SCORPION® 2 Data Logger for FSMA kill-step compliance. No other system makes it as simple to achieve desired levels of food safety and throughput. Get in touch with our headquarters in Sinking Spring, Pennsylvania, at (610) 678-5890 Ext. 2, or contact us online to explore our innovative products.