Temperature and humidity fluctuations in industrial ovens can lead to undesirable changes in your baked products. Consider the innovative digital meters from Reading Thermal to improve food safety and quality.

Reading Thermal, a Reading Bakery Systems brand headquartered in Sinking Spring, Pennsylvania, has been focused on measuring and understanding the commercial baking process for more than 25 years. We manufacture and support the SCORPION® 2 Profiling System which has become a standard in the baking industry.

The SCORPION® 2 Profiling System enables you to monitor actual in-process conditions and get the critical information you need to correct problems and maintain optimum process control. This powerful diagnostic tool is valued by commercial bakeries around the world for understanding and improving bakery proofing, baking, cooling and freezing processes, and for FSMA kill-step validation.

Measuring Oven Temperature

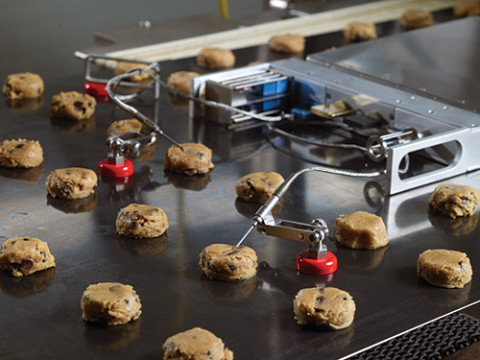

The Reading Thermal SCORPION® 2 Temperature Sensor Array is designed to measure temperature at product level, in fixed positions across the conveyor, and delivers a true representation of what your product is experiencing over time. Different types of pluggable sensors are available, including one designed for solid or tight mesh conveyors and one for open mesh conveyors.

The sensor array is connected to the SCORPION® 2 Data Logger and then travels through the oven with the product, yielding a precise picture of temperature from side-to-side and end-to-end.

There are 2 types of pluggable temperature sensors. One is an Air/Conveyor sensor that is designed to measure the surface temperature of the conveyor as well as the air temperature directly above the conveyor. This Sensor is designed for solid or tight mesh conveyors and measures air and band temperatures.

The other pluggable temperature sensor is an Air/Air sensor. It is designed to measure upper air temperature immediately above the conveyor, and lower air temperature of the air rising through the conveyor. It is meant for open mesh conveyors.

Measuring Oven Humidity

The SCORPION® 2 Digital Humidity Sensor provides a better way to measure humidity in your oven, proofer, dryer and cooling tunnel. Its breakthrough design provides a more accurate and reliable way to measure the absolute moisture content of the thermal environment.

The sensor contains a proprietary humidity sampling system with patent-pending Anti-Saturation Technology™ that allows measurements in high temperature and very high dew point processes. It travels through the oven with the product, yielding a precise profile of moisture it experiences.

Mechanically, the humidity sensor has a high temperature moisture sensor, a low temperature moisture sensor, and a bulk air or dry bulb temperature sensor. In ovens, the humidity sensor can be used to document the relationship between oven moisture and finished product moisture. In Cooling Tunnels, it can be used to monitor dew point temperature to prevent condensation on the product surface.

When you need to measure temperature and humidity in your industrial ovens, the state-of-the-art Reading Thermal SCORPION® 2 Profiling System and digital meters offer you an easy way to monitor actual in-process oven conditions. Contact us online or call us at (610) 678-5890 Ext. 2 to learn more about them.