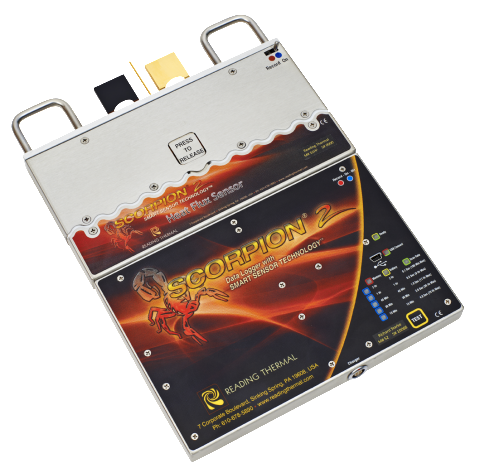

At Reading Thermal, we’re experts at helping bakeries control internal food temperature, which is the key to achieving food safety. Our SCORPION® 2 Profiling System is the industry standard, helping companies measure critical baking parameters (heat flux, humidity, temperature, and air velocity) more efficiently than ever before.

A Cornerstone of Safety

Controlling internal food temperature is not just a culinary technique; it’s the cornerstone of food safety in bakeries. From the moment ingredients are procured to the final product reaching consumers, maintaining precise internal temperatures is critical for preventing foodborne illnesses and ensuring the quality of baked goods. Here’s some information on why controlling internal food temperature is the key to achieving food safety.

- Ingredient handling: Proper storage of ingredients like eggs, dairy, and perishables at recommended temperatures, typically 40°F (4.4°C) or below, is imperative to inhibit bacterial growth and extend shelf life. Failure to store ingredients correctly can compromise the safety and freshness of baked goods before they even hit the oven.

- Dough preparation: Consistency in dough preparation is essential for achieving the desired texture and rising. Many recipes call for specific ingredient temperatures to ensure optimal mixing and kneading. For instance, chilled butter prevents the dough from becoming too warm and sticky, contributing to the dough’s structure and stability.

- Proofing and fermentation: During proofing and fermentation, maintaining controlled temperature and humidity levels is important for yeast activation and proper dough rising. Inadequate or excessive temperature and humidity can lead to inconsistent fermentation, affecting the texture, flavor, and overall quality of baked products.

- Baking: Each baked item has its optimal baking temperature, ranging from 375°F to 425°F (190°C to 220°C) for bread and lower temperatures for delicate pastries. Baking at the correct temperature ensures thorough cooking, desirable texture, and color development while minimizing the risk of undercooking or burning.

- Cooling and storage: Proper cooling and storage procedures are vital to prevent condensation, which can lead to moisture buildup and microbial growth, compromising product quality and safety. Baked goods should be cooled promptly on racks to allow airflow and then stored in airtight containers to maintain freshness.

How to Ensure Total Control

To achieve meticulous temperature control in bakeries, several strategies can be implemented:

- Utilize reliable thermometers and temperature probes to accurately monitor ingredient temperatures, dough consistency, and oven settings.

- Regularly calibrate equipment to ensure temperature accuracy and reliability.

- Implement robust temperature monitoring protocols and maintain meticulous records to track temperature variations and compliance with food safety standards.

- Provide comprehensive training to bakery staff on temperature control best practices, including proper handling, storage, and monitoring of ingredients and finished products.

- Establish stringent cleaning and sanitation procedures to prevent cross-contamination and maintain hygienic conditions in the bakery environment.

- Monitor ambient temperature and humidity levels in proofing and baking areas to optimize fermentation conditions and ensure consistent product quality.

Bakeries can produce safe, delicious baked goods that meet regulatory requirements and customer expectations by prioritizing temperature control at every stage of the baking process.

We’re Ready to Tell You More

Reading Thermal representatives are ready to provide more information on how the SCORPION® 2 Profiling System can help control internal food temperature, the key to achieving food safety. Please contact us online or call 610-678-5890.