If you don’t have enough information about your commercial oven to make reliable decisions about your bakery processes and products and believe an air flow checker would help, consider Reading Thermal.

Reading Thermal, headquartered in Sinking Spring, Pennsylvania, has been focused on measuring and understanding the commercial baking process for more than 25 years. We manufacture and support the SCORPION® 2 Data Logger which has become a standard in the baking industry and provides an easy way to validate your kill step for food safety.

By connecting our different smart sensors and sensor arrays to the SCORPION® 2 Data Logger and passing them through the oven with the product, the measurement system can capture the four main baking parameters: temperature of the environment (including the temperature of both the air and the oven belt surface), heat flux (energy transfer), humidity and air flow (velocity).

Measuring Oven Air Flow

Oven air velocity is the measurement of airflow inside the oven. The measurement is important because, along with other parameters, air velocity influences the coloration, texture, firmness, and baking time of your final product.

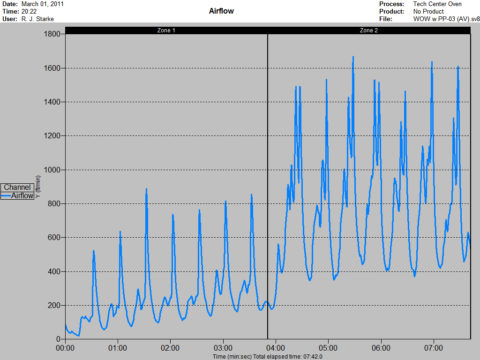

Air flow can be measured and recorded with the SCORPION® 2 Air Velocity Sensor. The sensor array delivers a precise picture of airflow patterns inside the oven. The sensors collect data, at product level, as the array travels through the oven. The number of sensors varies with the width of the conveyor.

For bread and buns, the SCORPION® 2 Temp + Airflow Sensor™ Array is designed to simultaneously profile airflow and temperature across the width of large tray and grid conveyor ovens exceeding 2m (6.5′). It features sensors spaced evenly across the length of an aluminum bar and contains four product probe inputs to measure product core temperature. The Array is available in three sizes to match the most popular bread oven conveyor widths as well as in custom sizes.

These sensor arrays are connected to the SCORPION® 2 Data Logger and travel through the process with the product, and the oven under full load, you with precise temperature and airflow measurements from side-to-side and end-to-end.

Keep in mind that the four key oven baking parameters – temperature, air velocity, heat flux and humidity – are interrelated. They work together to control the quality of your final product, e.g., humidity is affected by air velocity and temperature. Once you invest in the full-featured SCORPION® 2 Data Logger, you can add smart sensors at any time to explore other oven variables.

The air flow in your commercial bakery oven can have a major impact on the quality and consistency of your products. Air velocity checkers, or smart sensors and sensor arrays, from Reading Thermal can help you bake your products to perfection. Contact us online, or call us at (610) 678-5890 Ext. 2 to learn more about our innovative products.