A thermal profiling system for ovens could simply be a data logger, but a comprehensive analysis of your commercial ovens needs more than that. A thermal profile is developed by measuring time and temperature throughout the baking process, creating data reports that outline key variables for heat transfer, cooling periods, air velocity, humidity levels, and more. Compiling this data is integral for understanding the intricacies of your bakery processes, offering validation for current conditions, and alerting your team to issues affecting the final product.

Headquartered in Sinking Spring, Pennsylvania, Reading Thermal has been helping commercial bakers understand, optimize, and maintain their baking processes for 25 years. The baking process is complex, with variables ranging from product types and ingredients to industrial ovens. Our SCORPION® 2 Profiling System removes the guesswork in baking, giving you the confidence to make adjustments and decisions based on accurate profiles of your entire baking process.

What Measurements Does Thermal Profiling Take?

The quality of your products depends on four key baking parameters:

- Temperature

- Air Flow

- Energy Transfer

- Humidity

The level, location, and application of these variables have a tremendous impact on the final outcome of your product. Given how prone baked goods are to the conditions of their environment, lacking data on any of these parameters severely limits the amount of control and authority you have over the baking process across one or more lines. Our SCORPION® 2 Profiling System incorporates several solutions to monitor, compile, and report on the status of your baking parameters throughout every step of the process.

Temperature Sensor Array

By measuring the temperature at product level, our SCORPION® 2 Temperature Sensor Array assesses the status of your product temperature from the beginning of the process to the end, providing the most precise temperature readings it experiences in real time. As a result, a full load can be easily monitored with both side-to-side and end-to-end readings.

Digital Humidity Sensor

Humidity levels are becoming increasingly crucial as bakers look for ways to improve their products, which is why our SCORPION® 2 Profiling System includes a Digital Humidity Sensor. Accurately measuring the humidity in your ovens and control rooms will allow you to verify moisture levels in both heating and cooling environments, elevating control while also identifying how humidity levels affect your product.

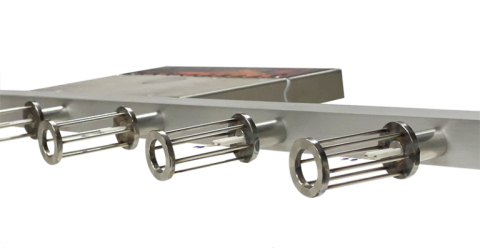

Digital Air Velocity Sensor Array

Airflow is responsible for controlling the level and amount of heat that’s spread throughout the baking process. Our Digital Air Velocity Sensor Array is designed with a state-of-the-art air velocity sensor that continuously monitors and reports airflow in real time. By adjusting the air velocity in a convection or radiant oven, you’re calibrating the amount of heat delivered to each product batch.

Heat Flux Sensor

The SCORPION® 2 Profiling System also features a Heat Flux Sensor designed to measure the heat transfer and rate of energy added to or removed from a product. This particular component is critical for controlling the microclimate inside your oven and is essential for applying consistent environment variables across one or more lines without compromising the overall consistency and quality of your products.

Thermal profiling systems for ovens operate on the principle that the best way to deliver a superior product is by understanding and controlling every element, variable, and factor in the process. If you’re interested in our services, call us at (610) 678-5890 Ext. 2, or contact us online for more details about our innovative products.