Profiling large Bread & Bun ovens like BakeTech, AMF and Turkington presents additional challenges regarding the placement of the SCORPION® 2 Equipment in the oven. Unlike biscuit and cracker tunnel ovens, where the SCORPION® 2 simply rides on the conveyor, bread & bun ovens require a specialized carrier. Placement is critical in order to produce accurate and repeatable data collection. Additionally, long bake times and the need to produce the Bake Cycle S-Curve have lead Reading Thermal to design a set of solutions for the Bread & Bun Baker.

Download Sample Bread Oven Profiling Report

Dr. Lin, founder of BakerPedia.com, discusses the critical nature of understanding and controlling steam in your Bread and Bun processes. Dr. Lin points out how doing an oven profile using the Reading Thermal Digital Humidity Sensor can help you obtain the desired product quality and throughput and identify factors keeping you from it.

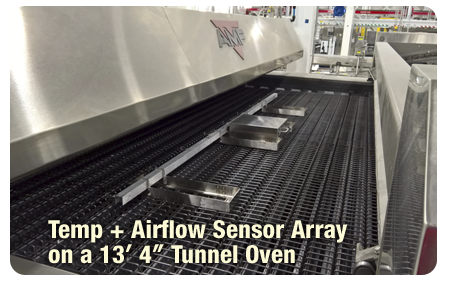

Temp+Airflow Sensor Array

Temp+Airflow Sensor Array

The Temp+Airflow Sensor Array is designed to simultaneously profile temperature and airflow across the width of large tray and grid conveyor ovens. The sensor array contains 9 Temp+Airflow sensors spaced evenly across the length of an aluminum bar. The array comes in 3 sizes to match the most popular bread oven conveyor widths. For easy transportation, the array folds to fit in a 1.4m (54″) long case.

Pan+Dough Probe

Pan+Dough Probe

This dual probe unit is placed under the bread or bun dough simultaneously capturing the pan/dough interface temperature and the dough core temperature. The copper spade is pressed against the pan, by the weight of the dough, measuring the critical pan/dough interface temperature. The vertical stainless steel probe penetrates the dough, to a fixed distance from the pan (1″ to 3″ in 0.25″ increments), measuring the dough core temperature used to produce the Bake Cycle S-Curve. The Pan+Dough Probe provides accurate repeatable results unattainable with hand-placed thermocouples. It connects to the Temperature Interface device which can accommodate 5 dual probes.

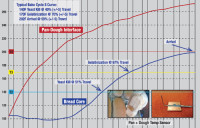

Bake Cycle S-Curve Analysis

Bake Cycle S-Curve Analysis

Bakers rely on Bake Cycle S-Curve Analysis to optimize the baking profile. This analysis provides critical insight needed to make adjustments to ingredients, bake time, and zone temperature settings. SCORPION® Software Version 8 (SV8) automatically calculates the three key S-Curve data points: Yeast Kill, Gelatinization and Arrival.

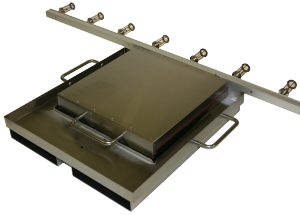

Specialized Carrier for Endless Conveyor Ovens (e.g. Bake Tech)

Specialized Carrier for Endless Conveyor Ovens (e.g. Bake Tech)

Tray Style Carrier for SCORPION® 2 Equipment provides easy loading and unloading on endless conveyors. The carrier, with SCORPION® 2, is inserted into the product flow replacing a bread or bun pan. Stainless Steel Magnetic Base Tray 406mm (16″) wide x 356mm (14″) long x 51mm (2″) high accommodates all SCORPION® 2 Equipment.

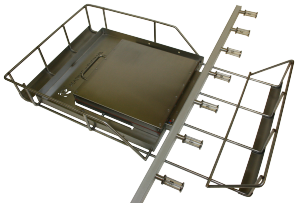

Specialized Carrier for Tray and Grid Conveyor Ovens (e.g. AMF, Turkington)

Specialized Carrier for Tray and Grid Conveyor Ovens (e.g. AMF, Turkington)

Basket Style Carrier for SCORPION® 2 Equipment provides easy loading and unloading on tray and grid conveyors. The carrier, with SCORPION® 2, is inserted into the product flow replacing a bread or bun pan. Stainless Steel Wire Frame Basket 381mm (15″) wide x 635mm (25″) long x 90mm (3.5″) high accommodates all SCORPION® 2 Equipment.